|

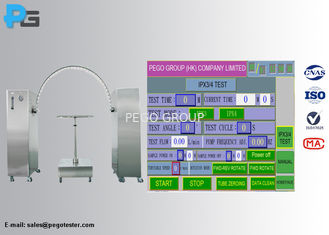

● Apply to IPX3 and IPX4 testing, R1/R2/S1/S2 testing

● Structure: adopts double pillars structure, easy to install and smooth running.

● The shells and turntable are made by SUS304# stainless steel, to make sure rustless for long time use.

● Built-in water tank, with ball valve to control the inflow, and with low water-level alarm to prevent from damage caused by hydropenia. The thermometer is to display the temperature of the tank.

● Oscillating tube drive: adopts step motors, made by PANASONIC (with features of low noise and high accuracy).

● Turntable drive: adopts Chinese superior step motors, the test speed and angle can be set up by touch screen, the speed is within the range of standard can not be adjustable, and can control the positive and negative direction (for live test, to prevent the winding) .

● Test time settable: 0~999min (adjustable), on-off time can be control by program: off (0~999min)-on (0~999min)-off (0~999min, It is apply to live test.

● Touch screen control:

A: IPX3 test: as per IEC60529 regarding IPX3 test.

B: IPX4 test: as per IEC60529 regarding IPX3 test.

C: User-defined: as per user’s demands, test time, angle, oscillating tube speed, and turntable speed can be freely to set up.

● Control system adopts 7 inch touch screen and PLC( Panasonic), the electrical components are made by LG, OMRON and other famous brands.

● Filter: equip with high accuracy filter, can filter out impurities, and the filter element can be changeable.

● Equip with necessary accessories, like filter element, pin, hex screw and etc.

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews