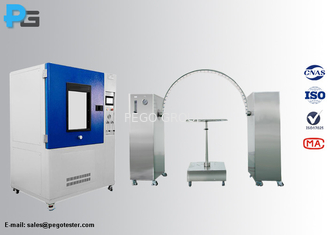

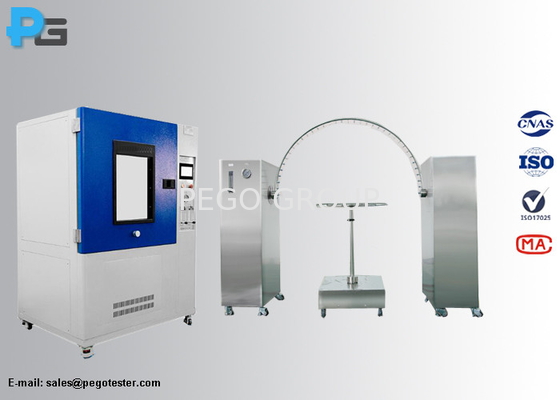

IEC 62196-1 Electric Vehicle IPX3 and IPX4 Oscillating Tube Waterproof Testing Machine

1. Introduction of oscillating tube waterproof testing machine:

Oscillating tube waterproof testing machine is designed according to IEC60529 figure 4, clause 14.2.3 and 14.2.4, and it's required by the standard IEC62196-1 clause 20.2. It is applied to verify protection against spraying (IPX3) and splashing water (IPX4) test, and widely used in the industries of electric vehicle, ve plugs and collectors, electronics, luminaire, electric components, auto parts and etc.. The IPX3 and IPX4 waterproof test equipment is consisted by oscillating tubes (R200 to R1600), turntable, water tank, control units (touch screen+PLC), flowmeter, pressure gauge and etc.. The oscillating tube is made of SUS304 stainless steel.

IPX3: the oscillating tube has spray holes over an arc of 60° either side of the centre point (the other holes are blocked), the total flow rate is adjusted as standard requirement, the enclosure to be tested is placed at the center point of the semicircle, the tube is caused to oscillate through an angle of 120°, 60° on either side of the vertical, the time for one complete oscillation (2*120°) being about 4s and test duration being 5 min. Then rotate the shell 90°in the horizontal direction, and test for 5 min, the maximum allowable radius of the swing tube is 1600mm.

IPX4: the oscillating tube has spray holes over the whole 180° of the semicircle, the total flow rate is adjusted according to the standard requirement, and measured with a flowmeter. The tube is caused to oscillate through an angle of almost 360°, 180° on either side of the vertical, and time for one complete oscillation (2*360°) being about 12s. The duration of the test is 10min. The support of test enclosure should be perforated to avoid becoming a water baffle; rotate the swing tube to the maximum in each direction, so that the shell will be splashed in all directions .

2. Features of oscillating tube waterproof testing machine:

● For IPX3 and IPX4 testing

● The shell of the equipment and turntable are made by SUS304# stainless steel, to ensure rustless.

● Adopts double pillars structure, easy to install and stable rotation.

● Equip with adjustable trundles, makes the equipment easy to move.

● The tank is under the equipment, auto to control the water level with the help of Water floating ball valve , and alarm at high or low level to protect from the damage caused by low water level.

● Oscillating tube drive: Adopts Panasonic serve motor, with features of low noise and high accuracy.

● Turntable drive: adopts Chinese branded step motor, can adjust the speed and angle by touch screen, and auto control the directions (fit for the samples to do live test).

● Time setting for power: power off: 0-999min-power on: 0-999min-power off: 0-999min

● Control components: 7 inch touch screen+ Panasonic PLC.

3. Parameter of oscillating tube waterproof testing machine

| Model |

IPX34C |

| Tube Radius |

R1600 |

R1400 |

R1200 |

R1000 |

R800 |

R600 |

R400 |

R200 |

| Outer size (L*W*H, m) |

4*3.2*2.8 |

3.6*3*2.6 |

3.2*2.4*2.4 |

2.85*2.02*2.350 |

2.4*1.8*2 |

2*1.4*1.8 |

/ |

/ |

| Delivery rate (L/min) |

0~10 |

0~10 |

0~6 |

0~6 |

0~4 |

0~3 |

/ |

/ |

| Diameter of turntable (mm) |

Φ1000 |

Φ1000 |

Φ800 |

Φ800 |

Φ600 |

Φ600 |

/ |

/ |

| Height of turntable (mm) |

1750~2350 |

1750~2350 |

1350~1950 |

1300~1700 |

950~1550 |

550~1000 |

/ |

/ |

| Aperture of nozzles (mm) |

0.4 |

| Inner diameter of tube |

15mm |

| Water tank capacity |

30L |

| Tube angle |

1200 (IPX3), 3600 (IPX4) or user-defined |

| Rotation speed of tube |

4s for 2*1200, 12s for 2*3600 or user defined |

| Material of tube |

SUS304 stainless steel |

| Rotation speed of turntable |

1~5r/min |

| Max. load-bearing capacity of turntable |

50KG |

| Turntable rotation method |

Forward or forward and reverse alternation |

| Protection |

Electric leakage, hydropenia, short circuit |

| Working power |

AC 220V/50Hz, 1KW (Live wire + neutral wire + protective ground wire) |

| Working conditions |

5℃~35℃ (temperature), ≤85% (R.H.), 86kPa~106kPa (pressure) |

| Accessories |

Water filter*1, test needle*100, 3-core cable*1 (3m) |

| Water source |

1).The user is required to configure a water source for the equipment at the installation site, with a water pressure not less than 0.2Mpa, and install a 4/8 inch faucet.

2).The faucet is not more than 2 meters away from the equipment

|

| Requirement for the site |

The ground is level, the drainage is unobstructed, the ground and walls are waterproofed, and the floor drain or drainage ditch is set |

| Requirement for power switch |

1). The user is required to configure the leakage protection air switch of the corresponding capacity for the equipment at the installation site, and this switch must be independent for the use of the equipment

2). It is forbidden to use knife switches or power sockets

3).The leakage protection air switch is not more than 2 meters away from the equipment

|

| Radius (mm) |

IPX3 |

IPX4 |

| Number of open holes |

Total water flow |

Number of open holes |

Total water flow |

| L/min |

L/h |

L/min |

L/h |

| 200 |

8 |

0.56 |

33.6 |

12 |

0.84 |

50.4 |

| 400 |

16 |

1.1 |

66 |

25 |

1.8 |

108 |

| 600 |

25 |

1.8 |

108 |

37 |

2.6 |

156 |

| 800 |

33 |

2.3 |

138 |

50 |

3.5 |

210 |

| 1000 |

41 |

2.9 |

174 |

62 |

4.3 |

258 |

| 1200 |

50 |

3.5 |

210 |

75 |

5.3 |

318 |

| 1400 |

58 |

4.1 |

246 |

87 |

6.1 |

366 |

| 1600 |

67 |

4.7 |

282 |

100 |

7.0 |

420 |

4. Picture of oscillating tube waterproof testing machine

5. Packing List of oscillating tube waterproof testing machine

| 1 |

Column box |

2 |

| 2 |

Swing Tube |

1 |

| 3 |

Turntable |

1 |

| 4 |

Blue Needle |

100 |

| 5 |

Stainless Steel Plug |

several |

| 6 |

0.35mm Needle |

1 |

| 7 |

O-ring seal |

1 |

| 8 |

Allen wrench |

1 |

| 9 |

Screws for swing tube |

6 |

| 10 |

Anilox tube |

6m |

| 11 |

Fastener |

4 |

| 12 |

Filter |

1 |

| 13 |

Filter Wrench |

1 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews